Power-Hungry New Technologies

After experiencing a partial nuclear meltdown in 1979, the Three Mile Island facility near Harrisburg, Pennsylvania became associated with nuclear disaster. The incident was so notorious that it sparked widespread mistrust of nuclear power at the time. Now, however, the facility is expected to come back online by 2028 to provide power to Microsoft data centers.

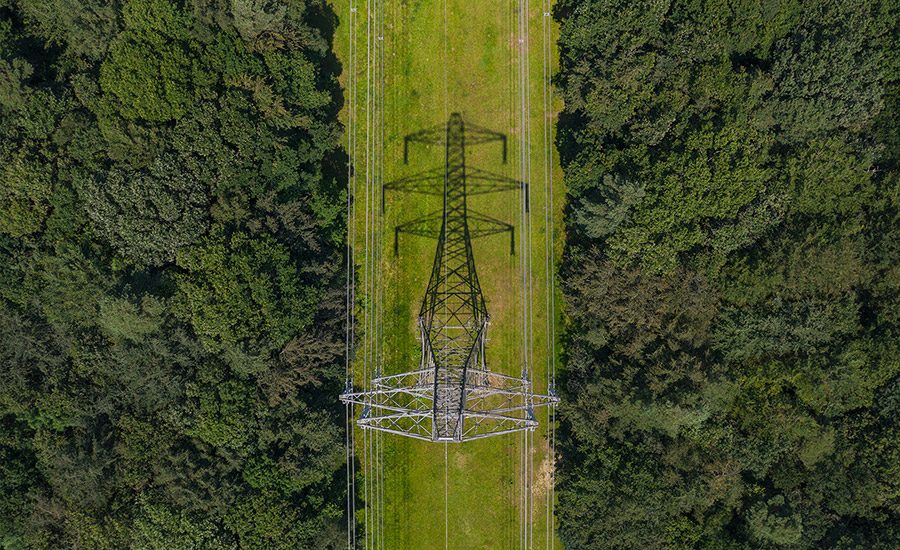

The rebirth of Three Mile Island isn’t an isolated fluke. Demand for new, power-hungry data centers to power AI, emission-free electric vehicles, and other technological advances has exploded, with facilities under construction and coming online across the globe. Joe Travis, senior director, solution engineering at Bentley, calls it one of the largest buildouts of infrastructure in human history.

“The amount of energy consumed by data centers is expected to quadruple in the next 20 years,” he said.

Electric utilities are under tremendous pressure to increase capacity, either through constructing new generation units, increasing transmission capacity, or simply maintaining aging assets. But skyrocketing demand isn’t the only thing adding to the workload.

As the world shifts to a low-carbon and electrified economy, clean energy delivery and energy efficiency are no longer optional. They are now essential and critical. Wind and solar farms are multiplying, supported by increasingly efficient battery storage. Biomass plants continue to bloom, and microgrids are an appealing option for supporting data centers. The energy transition will bring significant benefits, but getting there takes enormous amounts of time, money, and effort.

“We are really trying to help keep the grid on and keep the grid alive in a reliable and sustainable way,” Travis commented.

Though workloads are increasing as utilities race to catch up, less workers are available to tackle the jobs. Significant numbers of electrical engineers from the Baby Boomer generation are reaching retirement age, resulting in workforce shortages. Utilities can’t count on additional workers to overcome the increasing demand for new and upgraded projects.

More Videos →

Siloed Technology Can’t Keep Up

For decades, electrical engineers have adopted new digital technologies in an attempt to improve how they work. Though this shift has helped advance numerous aspects of designing, building, and maintaining electrical infrastructure, so much of the work remains separated with little to no collaboration. An array of specialized applications is now available for individual types of assets, but, too often, these assets work in isolation. A top-tier application for power generation can’t help if a transmission source fails.

“Applications must fit the entire lifecycle of the grid from generation following the electron through the entire grid all the way to the customers that use the energy,” Travis said.

Therefore, any truly effective technological solution must have an awareness of the entire electrical system. Utilities need a single, intuitive source of information that unites data for all assets so that workers can determine the status of all assets at a glance. With this knowledge, teams can enhance decision-making, speed up responses to any power outages, and determine when assets need to be repaired or replaced.

To achieve this whole system view, applications must be open and interoperable. Software designed for power generators and transmission equipment must be able to easily share information between them, rather than cause compatibility issues.

Interconnected data forms the foundation of a digital twin, which is a digital representation of a physical asset, process, or system, as well as the engineering information that allows teams to understand and model its performance. A digital twin empowers utilities with up-to-the-minute information about the operations and health of the entire electrical system, not just individual components. Furthermore, a digital twin created during the design of assets can be enriched with technical data, helping to inform construction, operations, and maintenance.

Complicated System, Small Footprint

To demonstrate how digital twins and unified workflows can benefit all elements of electrical transmission, let’s follow a hypothetical electron from the moment of power generation to its delivery into a customer’s outlet.

Electrons can begin their journey at modest generators meant to help with manufacturing power needs, or they could be produced at massive stations meant to light up entire regions. For example, Baihetan Hydropower Station, located on the upper reaches of the Yangtze River in China, is the second-largest hydro facility in the world, consisting of 16 power generation units with a capacity of 1 gigawatt each. But all that generated power can’t help if it isn’t delivered to customers. Specifically, Chinese officials wanted power from the station to be transmitted 2,000 kilometers away to eastern China, solving ongoing power shortages and providing carbon-free energy.

The ambitious goal would require a massive amount of equipment, but space was limited. As a result, Southwest Electric Power Design Institute Co., Ltd. of China Power Engineering Consulting Group (SWEPDI) developed a “three stations in one” concept that combines two sending-end converter stations with the main converter station, making the facility more compact.

However, bringing that plan to life meant rethinking everything and asking many questions, Travis said.

“What about the pilings that need to go into the ground,” he asked. “Or the structural capabilities of the utility network? What types of materials need to be used, some built far away while others are manufactured on-site?”

The answer to these questions was to create a digital twin of the entire site. Using Bentley applications, they used the virtual replica of the project to determine how to save space, what materials to use, and the length of each pile foundation to provide stability in the varied terrain.

With the insights gained from the digital twin, SWEPDI found ways to overcome technical hurdles, optimize the site design, and lower the footprint. In the end, they reduced the amount of land needed by 10 hectares, shortened the development schedule by 70 days, and saved CNY 7 million.

Preserving a Critical Transmission Bottleneck

Once the hypothetical electron is generated and sent out, it needs a reliable transmission path. Often, due to geographical constraints, transmission to a specific area becomes restricted to a single line. If the assets supporting that bottleneck fail, customers in that area could face a blackout lasting weeks or more.

That’s the situation faced by utilities LG&E and KU Energy. The Ohio Falls Generating Station, built on the Ohio River in Kentucky nearly a century ago, depends on two vintage lattice towers to transmit electricity across the water. Since the towers were built at the same time as the station in the 1920s, they gradually weathered and weakened over the last century. Something had to be done to keep the energy flowing, but completely replacing the towers could have been prohibitively expensive and increase time to operation.

“In this case, the question was ‘can we use an older structure that’s already there, or do we have to place time, money, and investment into building a new one?’” asked Travis.

Utility infrastructure asset management company Exo realized that the best way to determine the current health of the towers, and the most effective way to rehabilitate them would be to create a digital twin. They first used drones to capture images of the tower from every angle, then turned to Bentley iTwin Capture and Power Line Systems applications to create the digital twin.

The model gave Exo a convenient, accurate replica of the towers, helping them to accurately measure gaps and assess corrosion from the comfort of their office. As a result, they created a plan to rehabilitate instead of replace, saving approximately USD 80 million and eliminating up to 10 years of planning and permitting.

Effective Maintenance in the Wilderness

Now, let’s follow the electron to an electrical substation near its final stop with a customer. Essential Energy, like most utilities, manages a wide set of substations. Unlike most utilities, their assets are in the Australian outback, far from metro areas and often in treacherous terrain. These substations, which date back to the 1960s, need maintenance and upgrades to serve a growing population. However, getting to them can be a challenge.

“Can I get a truck through here with the right transformer and the right tools? The last thing you want to do is drive 500 kilometers to the Outback and realize you forgot the right tool or the transformer on the truck won’t fit where you need it to go,” explained Travis.

A digital twin of their system would give Essential Energy greater clarity into the status of every substation. They began by using drones and Bentley iTwin Capture to not only capture imagery of not just the substations, but the environment around it. That way, maintenance teams can prepare themselves for any kind of hazard. They combined the virtual environments with an intelligent digital design system, which automated drafting and enabled virtual design reviews. As a result, they lowered costs by 50%, reduced travel and related carbon emissions, and improved the quality of repairs and upgrades to ensure a resilient power supply to the rural area.

Connecting It All With a Digital Twin

As these case studies illustrate, every electron generated depends on an array of complicated equipment and assets to get where it needs to go. Digital twins and the open technology that supports them can provide owners and operators with intuitive overviews of every element of the electrical system, without having to crack open data silos or try to find those with deep technical knowledge when something goes wrong.

“Having a unified view of the entire digital twin provides increased transparency to what exists today, and what we can plan and design for the future,” Travis said.

As data is created or edited by the ecosystem of subcontractors and vendors, the digital twin remains up-to-date and reflects conditions in a near real-time environment, so that everyone is seeing the same thing, and stakeholders can stay informed. Utilities can react faster to growing demand, and new elements can be easily incorporated into the existing system. With digital twins, utilities can overcome emerging challenges and keep those electrons moving.

Author Bio

Joe Travis has a rich background in the energy sector, having worked with major software vendors and leading teams in various roles. At Bentley Systems, he has been instrumental in improving infrastructure software and guiding large infrastructure projects. His expertise spans GIS/GPS technologies and electric distribution networks, making him a valuable asset to Bentley Systems’ energy industry solutions. Joe’s leadership and technical knowledge have been instrumental in modernizing the energy sector and supporting its transition to renewable energy sources.