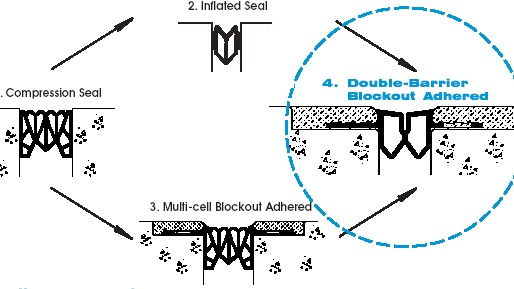

1. Compression Seal

Description: Multi-cell Neoprene extrusion installed with epoxy “lubricating adhesive” applied to the joint face.

Advantages:

-

Premier technology post-World War II.

-

Foundation for modern extruded expansion joint seals.

Limitations:

-

Anchoring system relies on adhesive in tension, the weakest method.

-

Requires force-compression in the joint.

-

Limited movement due to complex internal webbing.

-

Compression set leads to permanent loss of backpressure.

-

Rigid structure and poor anchoring cannot handle vertical differential deflection.

-

Neoprene thermoplastic rubber cannot be heat-welded; repairs must be glued, which dries out over time.

2. Inflated Seal

Description: Double or single barrier Neoprene thermoset rubber extrusion with joint face-applied epoxy “adhesive-in-tension” anchoring system. Seal is inflated during installation to improve bond.

Evolutionary Advantages:

-

Reduced interior webbing increases movement range over compression seals.

Disadvantages:

-

Anchoring system relies on adhesive in tension.

-

Bond line stressed by vertical deflection, gravel, and lateral movement.

-

Does not protect joint edge; requires elastomeric header for waterproofing.

-

Neoprene thermoset rubber cannot be heat-welded; repairs must be glued, which is not UV stable and dries out over time.

-

Poor extrusion tolerances yield excessive bulk at flexural nodes, stressing the epoxy bond.

-

Dependent on extremely smooth joint face.

3. Multi-Cell Blockout Adhered

Description: Blockout-anchored multi-cell extrusion with integral punched flanges encapsulated in elastomeric concrete nosing material.

Evolutionary Advantages:

-

Superior anchoring system compared to compression and inflated seals.

-

Elastomeric concrete nosing encapsulates punched flanges, using adhesive in shear, the strongest method.

-

Over 45 square inches of adhesive in shear per foot of seal.

-

Not affected by minor joint face irregularities.

Disadvantages:

-

Limited movement due to complex interior webbing.

-

Rigid structure inhibits vertical differential deflection.

-

Retrofitting requires cutting of blockouts; new construction can form blockouts.

4. Double Barrier Blockout Adhered

Description: Double-Barrier Santoprene thermoplastic rubber extrusion with integral punched flanges encapsulated in elastomeric concrete nosing material.

Evolutionary Advantages:

-

Combines high movement of double barrier inflated seal with secure blockout mounting.

-

Elastomeric concrete nosing encapsulates punched flanges, using adhesive in shear, the strongest method.

At Dseal, we are committed to advancing the technology of extruded expansion joint seals, ensuring durability, flexibility, and superior performance for all your construction needs.