In high-risk industries—like oil & gas, mining, construction, and manufacturing—workplace safety conversations often focus on preventing accidents. But there’s another side to safety that’s just as critical: protecting the long-term health of workers.

This is where the Occupational Health Strategy comes in. It’s not just about compliance with safety rules, but about building a structured, long-term plan that reduces exposure to hazards, improves workplace conditions, and keeps workers fit for their jobs for years to come.

The challenge is that in many industrial sites, health strategies are still based on incomplete reports, occasional inspections, and delayed feedback. This often results in reactive measures—fixing problems only after someone gets hurt or sick—rather than preventing them in the first place.

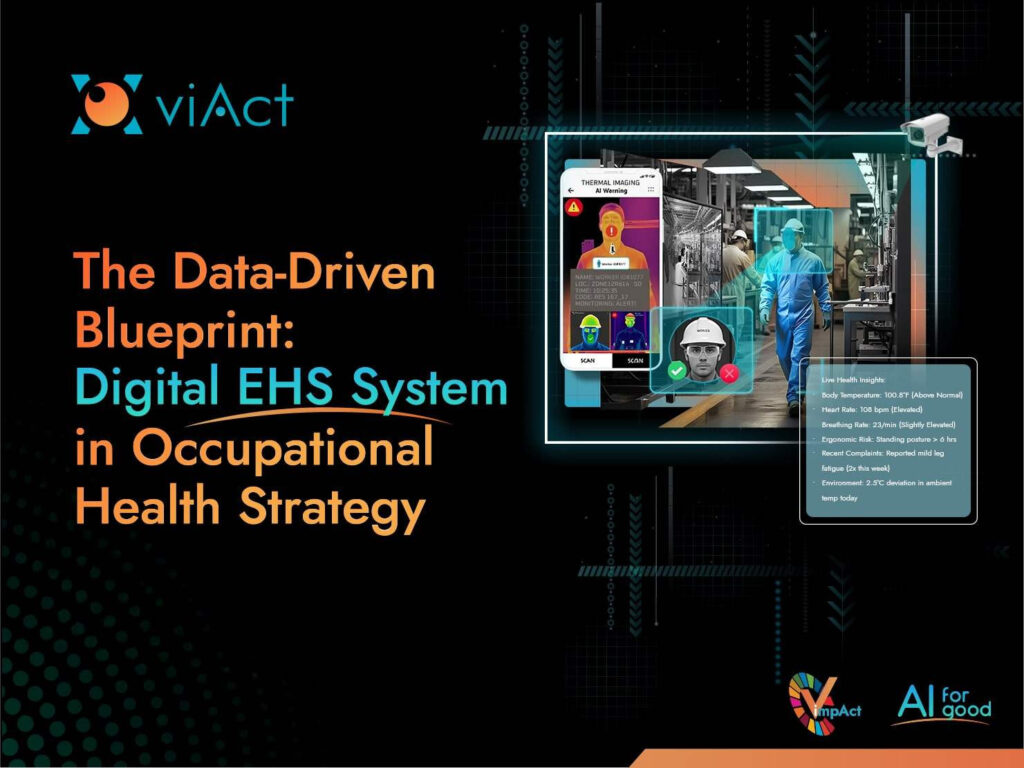

Today, with digital EHS (Environmental, Health & Safety) systems, it’s possible to design occupational health strategies that are powered by real-time data. These systems create a data-driven blueprint—a living, evolving plan that adapts as workplace conditions change.

Understanding Occupational Health Strategy in Industrial Sites

An Occupational Health Strategy is the roadmap a company follows to manage and reduce workplace health risks.

For high-risk sites, this can cover a wide range of areas, such as:

-

Controlling exposure to dust, chemicals, or extreme temperatures

-

Monitoring physical strain from repetitive or heavy tasks

-

Identifying and addressing unsafe work behaviours before they cause harm

-

Designing workstations and work shifts to reduce ergonomic strain

However, the ultimate goal here is to protect workers from both immediate injuries and long-term health problems.

Common Challenges in Creating an Effective EHS Strategy

Even with the best intentions and EHS experts in the field, many occupational health strategies fall short because of a few simple but critical issues:

1. Delayed or Missing Reports

Traditional monitoring systems at work, although they record critical instances like near miss reporting or unsafe behaviours, aren’t put to analysis right away. For example, if a worker repeatedly lifts heavy loads without proper posture in a manufacturing unit but no one logs it, the risk of musculoskeletal diseases (MSDs) goes unnoticed until it’s too late.

2. Fragmented Information

Health data might come from multiple sources in a traditional setting. These include a paper-based accumulation of incident reports, environmental monitoring devices, medical records, and supervisor observations. If these aren’t connected through a holistic analytical process, it’s hard to see the full picture.

3. Inconsistent Monitoring

Many workplaces only check for workplace safety risks when an injury is reported, instead of monitoring regularly without any significant threat. This restricts minimal risks like slips & trips, prolonged exposure to dust, or occasional removal of PPE from escalating into major instances of worker health and safety.

4. Limited Visibility

Supervisors and EHS leaders with traditional tools of monitoring can’t be everywhere at once. Today’s industrial areas have more than 100 workers across multiple sites working simultaneously. Unsafe shortcuts—like removing a helmet for comfort in a high-risk zone, walking through a restricted area to minimise distance, or minor chemical splashes—often go unnoticed until an incident occurs.

5. No Real-Time Feedback

One of the disadvantages of industrial operations in a traditional EHS system is no real-time indication. If it takes days or weeks for health and safety issues to be reviewed, corrective action is delayed, and workers remain exposed to risks for a prolonged period of time.

These challenges mean that strategies are often reactive—acting after harm occurs—instead of preventive.

Why a Data-Driven Blueprint Matters

The high-risk industrial hazards are prone to dynamic conditions that require updates daily, or even hourly. An occupational health and safety strategy that is updated once a year is simply not enough.

-

Strategies become adaptable and scalable to changing conditions

-

Decision-making is evidence-based and no longer relies on observations and experience

-

Risks are addressed before they cause harm

-

Worker trust increases because issues are resolved faster and more transparently

A safety ecosystem built with trust and confidence stems through the workplaces when the strategies are based on strong data-based analytical insights.

How a Digital EHS System Creates a Data-Driven Blueprint

A smart AI-based EHS platform changes how occupational health strategies are built and managed. Instead of relying on occasional inspections or manual logs, it collects continuous, real-time data from multiple sources, processes it intelligently, and delivers insights that can be acted on immediately.

Here’s how it works in practice:

1. Bringing All Health Data Together

In high-risk industrial environments, health and safety data is often scattered across multiple systems—incident reports stored in one place, PPE compliance checks in another, environmental readings in yet another. An AI-powered EHS system simplifies this by gathering information from all sources into a centralized management platform.

This can include reports of near misses, daily PPE compliance checks, readings from environmental sensors tracking heat, noise, or dust levels, findings from ergonomic assessments, and even behavioural observations collected through video monitoring.

By centralizing the data, EHS teams have a complete picture of workplace conditions without having to piece it together manually. For example, if an offshore rig experiences several noise-related complaints, the centralized records make it easy to monitor red zones and cross-check these with equipment operation logs and maintenance schedules to identify patterns.

2. Turning Observations into Actionable Insights

Simply collecting data is not enough, especially when a modern-day occupational health strategy is designed. What matters is turning it into insights that lead to concrete action. For instance, if records show that near misses frequently occur in a particular warehouse aisle, it could indicate an equipment layout issue or a procedural gap that needs addressing.

Behavioural observations are equally considered for designing the strategy blueprint, which is often overlooked. If reports or video data reveal that workers tend to bypass safety barriers during night shifts, this could be a result of reduced supervision or inadequate lighting.

By analysing these trends over time, EHS teams can direct interventions where they will have the most impact, ensuring strategies are based on real-world patterns rather than assumptions.

3. Alignment with Industry Standards and Requirements

Every industry, especially the fast-moving industrial settings, operates under strict regulations for workplace safety. Modern Computer vision-based EHS solutions provide real-time alerts to supervisors when unsafe conditions are identified, aligning with globally followed standards such as the Occupational Safety and Health Administration (OSHA).

For example, OSHA’s standards require workers exposed to high-noise environments, one where a worker needs to raise their voice to speak to someone 3 feet away, to wear adequate PPE with hearing protection. When AI-guided EHS system operates in a high-noise zone, any worker without hearing aid PPE is reported to the safety team, ensuring compliance before a violation occurs.

4. Predicting and Preventing Future Risks

Data collected over time can be used not just for analysing current risks, but also for predicting future ones. Historical records help identify seasonal or operational patterns that influence workplace hazards. For instance, mining sites may see a rise in dust levels during dry, windy months, increasing the risk of respiratory issues.

Likewise, in outdoor operations, mid-summer periods may correlate with higher heat stress cases, especially in physically demanding roles. With this foresight, preventive measures—such as adjusting shift timings, improving ventilation, or rotating tasks—can be built into occupational health plans before risks materialise. Predictive planning ensures that safety is not just reactive but anticipatory.

Case Study — From Strain to Strength: How a Singapore Construction Site Cut Back Injuries by 48%

The construction site working on a multi-tower residential project in Singapore, faced a recurring issue — increasing cases of lower back strain among workers handling rebar and formwork panels. Despite periodic safety talks, the problem persisted, and site productivity was impacted by both injuries and absenteeism.

In early 2025, viAct integrated EHS management platform was deployed across the site. Based on data insights here’s how the step-by-step strategy unfolded.

Step 1 — Mapping the Risks

|

An occupational health strategy is only as strong as the information it’s built on. In the past, that meant relying on supervisor reports, safety audits, and occasional inspections.

The result isn’t just compliance—it’s healthier workers, safer operations, and a workplace culture that values prevention over reaction.

1. What are the long-term benefits of a data-driven occupational health strategy?

A data-driven blueprint ensures:

-

Reduced injury rates through early hazard identification.

-

Lower compensation and downtime costs.

-

Healthier, more productive workers with fewer chronic conditions. Over time, this shifts a company from reactive firefighting to proactive health and safety culture.

2. Can EHS monitoring platform be scaled across multiple sites?

Absolutely. A well-designed EHS platform like viAct can connect data from every site into one central dashboard. For example, a global oil & gas company used it to compare PPE compliance rates in rigs across the North Sea, Middle East, and Asia in real time. This scalability ensures the same safety benchmarks are applied company-wide, without losing local context.

3. Is viAct’s EHS software available only in Singapore?

No—while viAct has projects in Singapore, it is designed for deployment in multiple regions. It’s already been implemented in sectors like construction, mining, and oil & gas across Asia, the Middle East, and Europe. The software is currently deployed in regions like Hong Kong, Saudi Arabia, United Arab Emirates (UAE), Qatar, Oman, Bahrain, Kuwait, and other GCC and Middle East markets, as well as India, Southeast Asia, Australia, Europe, and North America.

4. How quickly can an AI-powered system show results?

Results can be seen in weeks. In one Middle Eastern construction firm, digitising incident logs and PPE compliance checks cut reporting delays from 4 days to 1 hour. Within 3 months, targeted retraining reduced repeat incidents by 38%. The key is that improvements start immediately—because risks are addressed in real time, not weeks after the fact.

5. Is data from EHS analytics platform accurate to rely on for decision-making?

Yes—modern digital safety platforms use automated collection from multiple trusted sources, such as IoT sensors, video analytics, and digital incident logs, reducing human error. Accuracy is strengthened because:

-

Data is gathered in real time, not reconstructed later.

-

Multiple sources cross-verify the same event.

-

Historical trends can confirm whether a pattern is genuine or a one-off anomaly.

The AI-Driven EHS Occupational Health Strategy is Here!